Anchor Safety

Why is it so Important?

Guy line anchors are one of the most over looked safety hazards in the oil industry today. There are guy line anchors still in use today that were installed as far back as 50+ years ago. Most of the older types were made out of Sucker Rod, or rolled steel that were not properly galvanized to protect against Corrosion and do not meet current OSHA Safety Standards.

What we offer in solving all Guy Line Hazards is a complete anchor services. At each location, we will locate all anchors and test each anchor to a desired pull test. The pull test will be done with a certified testing unit. Each pull will be recorded on a chart recorder which will be turned into your well file. After testing, we will mark the location of the anchor and paint a marker. An anchor schematic will be sent with distances from anchor to well and test information. A monthly update will be emailed to individuals in charge of well work to insure they stay informed on wells with anchors that may be due for testing.

The next time you have the need for a pulling unit to rig up on this location, you will not have to worry about the anchors. They will be easy to locate, cutting down on standby or down time for the pulling unit. In addition, you will have no safety concerns or hazards with regards to the quality of the anchors.

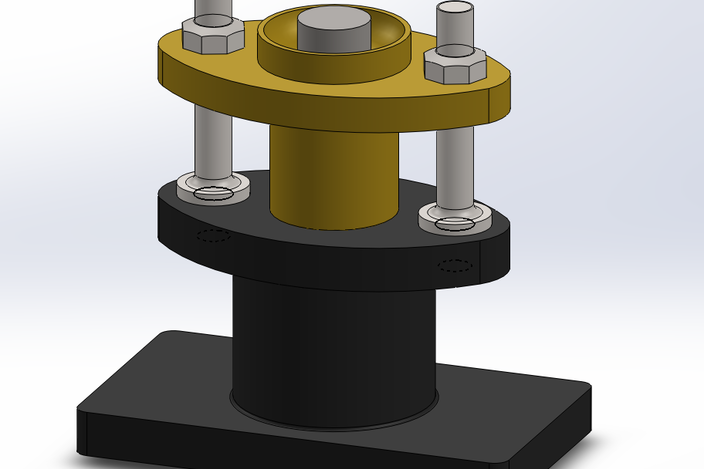

Pipeline Support Anchoring: This system can be used to Tie down High Pressure pipelines, Tie-down (Frac) Bleed off Pipelines and can also be used to achieve Instant Pipeline support which replaces the expensive systems currently used in most oilfields. The system is adjustable to the terrain and requires no advance site preparation, No Concrete required, Support anchors can be installed and pipelines set immediately. Salvageable supports that can be removed and relocated and reused. This all adds up to substantial cost savings.